Retaining Wall Inspections Fundamentals Explained

Wiki Article

Not known Facts About Retaining Wall Inspections

Table of ContentsMore About Retaining Wall Inspections9 Easy Facts About Retaining Wall Inspections ExplainedSome Known Details About Retaining Wall Inspections 4 Simple Techniques For Retaining Wall Inspections

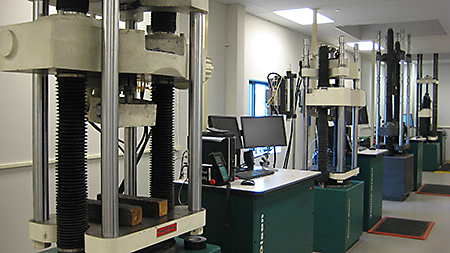

The influence of Construction Materials Screening reaches much past whether a particular material passes evaluation or not. The honesty of a highway, structure, or various other building and construction structures can easily be compromised if materials checking solutions are not correctly finished, which can lead to pricey results on project construction. At ARIAS, we understand how our solutions impact a task's layout, construction, and also efficiency.

Our accredited as well as educated staff give a myriad of Construction Materials Checking solutions during as well as after building and construction. These solutions help professionals during building, supply a verification to proprietors, designers, and building authorities that tasks will certainly execute as intended, and promote post-construction investigation of aspects not doing correctly. Our solutions listed might be given on an on-call or full time basis, with laboratory testing done in our neighborhood workplaces - retaining wall inspections.

Arias offers High quality Guarantee, Quality Assurance, as well as Unique Inspections in several stages of building consisting of (yet not limited to):.

The Single Strategy To Use For Retaining Wall Inspections

Polymer screening is the process of evaluating the mechanical, thermal and chemical homes of polymers, which are large molecules composed of repeating architectural devices. These examinations are used to figure out the viability of a polymer for a specific application as well as to make sure that it fulfills industry standards for quality and performance.Evaluating these products helps to make sure that they fulfill the desired requirements and also perform as anticipated in their designated application. One usual type of polymer screening is, which gauges the product's toughness, strength, as well as contortion characteristics.

These tests can aid determine the polymer's viability for usage in high-stress applications, such as vehicle components or construction materials. One more vital kind of polymer testing is, which gauges the product's actions at various temperature levels.

This can include examinations such as acid resistance, alkali resistance, and also solvent resistance. These tests can aid figure out the polymer's viability for usage in chemical processing or storage applications. In general, polymer testing is an essential action in ensuring that a polymer meets the needed residential properties as well as criteria for use in numerous sectors.

The 45-Second Trick For Retaining Wall Inspections

Polymer testing is essential for numerous factors: Fulfilling criteria of high quality. As an example, a supplier might make use of testing to make sure that a polymer product has the correct physical residential properties such as stamina, adaptability, or resistance to wear. Making sure the products are safe for their planned use and don't offer any kind of health dangers to human beings or the he said environment.

Evaluating figures out the long life of the items, which has a large influence on the life cycle of the item, therefore influencing costs as well as client satisfaction. Micom gives a broad variety of polymer testing solutions (retaining wall inspections).

Our polymer testing engineers can give you with a checklist of proper examinations to confirm that your product meets your specs. The polymer testing services provided by our research laboratory assistance you: Fulfill all relevant nationwide and international requirements.

Flatwise Tensile Toughness ASTM C297 Effect ASTM D2794 Covering Flexibility ASTM D522 Plastics Mechanical Prop. ASTM D2990 Tensile Toughness ASTM D638 Peeling Off Toughness ASTM D1781 Compensation. Str. Inflexible Plastics ASTM D695 Finishing Adhesion Tape ASTM D3359 Flexural Strength ASTM D790, ASTM D3043 Foam ASTM D3574 Particular Gravity ASTM D792 Taber Abrasion ASTM D4060 Bit Board Evaluating ASTM D1037 Composite Materials ASTM D4762 Rigid Cellular Plastics ASTM D1623 Wood-Bonding Adhesives ASTM D5574 It is essential to note that the examination choice will certainly rely on the polymer kind, use as well as specific demands.

5 Easy Facts About Retaining Wall Inspections Explained

You can count on Micom's experienced group to lead you in picking the right polymer tests for your application. Call us today to figure out how our polymer testing here services can ensure the top quality, resilience and also safety of your item. For additional details on different paint, finishing and polymer testing solutions, please see the following web pages: Material Testing, Accelerated Aging, Coating Testing, ASTM Testing.

Material testing is essential in the verification process, establishing the appropriate material and also dependability for an application as well as conference governing and standardized requirements. The materials that go right into all items, devices and also innovations we trust day-to-day must be completely examined for safety see here and security, performance, as well as various other standards, prior to the initial product can come off the production line.

Report this wiki page